Additive Manufacturing in 2025: Changing the Way We Make Everything

What Is Additive or 3D Manufacturing?

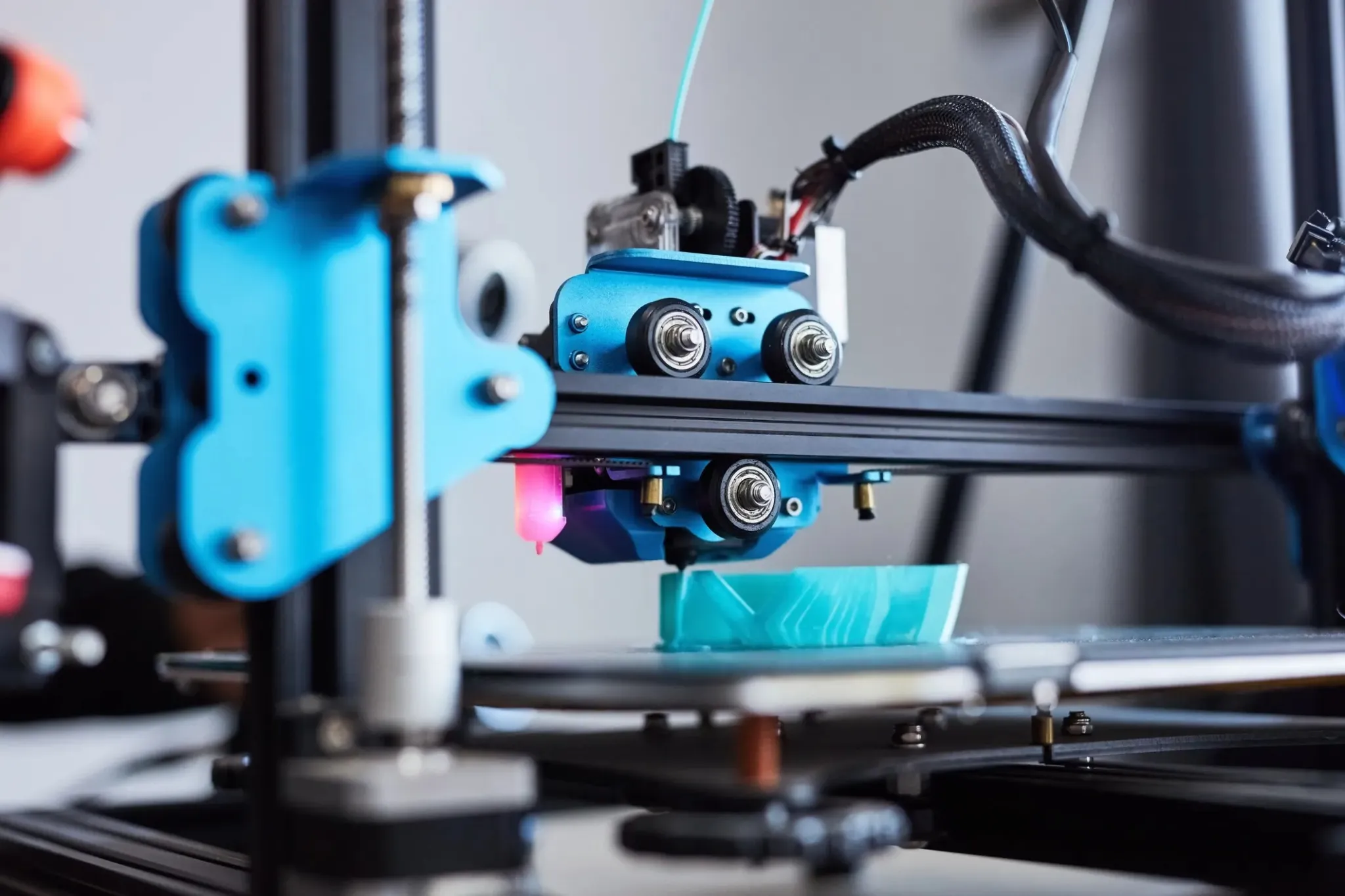

Walk into any modern workshop or research lab in 2025, and you’ll probably see a bunch of 3D printers at work, building objects layer by layer. 3D or Additive manufacturing (AM) refers to the creation of objects from a digital blueprint by the addition of layer upon layer of material, which can range from thermoplastics and resins to metal powders and ceramics. Whereas traditional manufacturing uses the technique of machining or moulding, additive manufacturing builds up parts from nothing—often with impressive precision and almost no waste.

How did it come about?

3D manufacturing has come a long way from its origin as a prototyping technology way back in the early 1980s. Prototyping is the process of creating an initial model, sample or module of a product in order to evaluate its design, functionality and feasibility before going on to produce its final version. A key breakthrough in prototyping technology happened in 1986, when an American Engineer Chuck Hull invented a technology called Stereolithography (SLA), which built objects layer by layer by curing photosensitive resin with UV light. This simplified and sped up the prototyping process and allowed companies to quickly create detailed plastic prototypes for testing. Initially, this technology used large and expensive 3D printers which were used by manufacturing companies to prototype plastic models. New technologies broadened the capabilities of 3D printing over time and resulted in desktop 3D printers in the 2000s, which could be used even by hobbyists.

Additive manufacturing has been reshaping industries, bringing speed, flexibility, and innovation to fields as diverse as aerospace, healthcare, and consumer products.

How does 3D printing actually work?

3D printing is like drawing a picture, but instead of lines on paper, a composite is created by stacking up successive layers of material like layers of icing on a cake to form the final three-dimensional solid object. The layers follow a digital design split into very thin horizontal slices. Slicing software plays a crucial role in building a 3D object layer by layer by converting the digital 3D model into specific instructions that the 3D printer can follow.

What is Slicing Software and what role does it play in 3D printing?

This software “slices” the 3D model into many thin horizontal layers and calculates the precise path the printer’s nozzle or laser must take for each layer. This includes determining how much material to deposit, where to move the printer head, and how each layer should be constructed to form the object accurately.

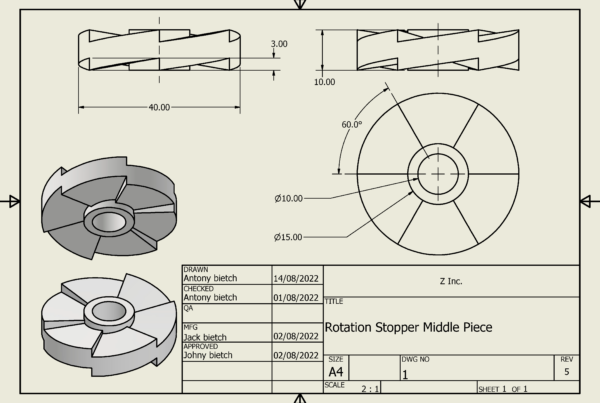

Do 3D Printers produce shapes within certain geometric constraints?

3D printers are extremely flexible and can create a vast range of shapes, including extremely complex and intricate designs, because they build objects layer by layer from a digital model. This means there isn’t a fixed list of shapes—they can make almost anything you can design. However, there are some practical limits in terms of maximum size which depends on the size of the printer, the printer’s resolution which can restrict the printing of very fine details and problems with overhangs: parts that stick out and therefore need extra support structures during printing to prevent sagging.

Overall, however, the versatility of 3D printers goes far beyond what most traditional manufacturing allows.

What are the key advantages of Additive Manufacturing?

- Quick Prototyping: Making test models is much quicker—what used to take months can now be done in just days. This helps engineers try out ideas faster and fix problems more easily and cheaply.

- Versatility: 3D printing can create shapes that are impossible or very hard to make with regular methods.

- Less Waste: 3D printing uses only as much material as needed to build the part, so there’s very little waste. Any leftover material can often be reused, making it better for the environment.

- Fewer Inventories: Companies can print spare parts or products when needed, instead of keeping lots of items in storage. This saves space and money.

- Easy Customization: Each item can be made exactly how it needs to be, without high extra costs. This is very useful for things like medical implants and unique consumer products.

- Less Energy requirement: 3D printing requires less energy and uses smaller machines compared to traditional methods that cut or shape big blocks of material.

In short, additive manufacturing is fast, flexible, more eco-friendly, and makes it easier to create special or complex items.

What are the Real-World Applications of Additive Manufacturing?

- Bio-printing

AM has become indispensable for custom prosthetics, dental implants, hearing aids, surgical instruments, and even tissue scaffolds. Perfectly tailored implants that fit each patient’s anatomy ensure improved outcomes and reduced complications.

- Aerospace & Defense

Titanium and advanced alloys are being used to manufacture jet engines, satellite parts, and structural components which are lighter and stronger and result in more fuel-efficient aircraft. Boeing and Airbus have adopted 3D printing for critical engine and airframe parts.

- Automotive Industry

Innovative automakers like BMW and startup manufacturers are using AM for custom fixtures, lightweight components, spare parts for classic models, and rapid prototyping. The process also enables the production of parts previously impossible with casting or machining.

- Consumer Products

Eyewear, fashion accessories, sports gear, and even shoes are now personalized and produced on demand. AM allows designers to experiment with bolder forms and custom fits—for example, glasses stems shaped to a user’s ear or running shoes manufactured to the exact shape of a foot.

- The Energy Sector

The oil, gas, and power sectors use 3D printing to build robust parts like turbine blades or heat exchangers, often with complex internal channels for improved efficiency.

What are the challenges with 3D manufacturing?

- Speed & Scale: While AM excels at custom items or small batches, for massive production runs, traditional methods can still be faster and cheaper.

- Material Properties: 3D-printed parts can sometimes lack the same strength, finish, or performance as those made by casting, especially those used in highly stressed applications.

- Post-Processing Needs: Many printed items require support removal, surface finishing, or heat treatment, adding to costs or production time.

- Skills Gap: Digital designs for AM require a different mindset than for machining or molding and there is still a shortage of skilled designers and technicians who can design these.

- Initial Costs: Setting up industrial AM equipment can require significant investment, though costs are gradually falling as technology matures.

So what is the Road Ahead for 3D Printing?

3D printing isn’t just for science projects anymore — it’s a key technology used in industries, healthcare, and many other areas. It allows making things in a way that’s more flexible, innovative, and better for the environment. 3D printers will become simpler to use and smart programs will enable people who aren’t expert to create professional quality objects. They will be able to set themselves up and let you know when they need fixing. New materials are being developed too — printing living tissues for medicine is getting closer, and eco-friendly materials that can be recycled or broken down naturally will help protect the environment. 3D printing will work together with traditional manufacturing methods, not replace them. Using both will give the best balance of cost, speed, and detail.